The DrillSIM:5000 Classic is the global standard of advanced drilling and well control simulation. It is a tactile simulator with a manual brake.

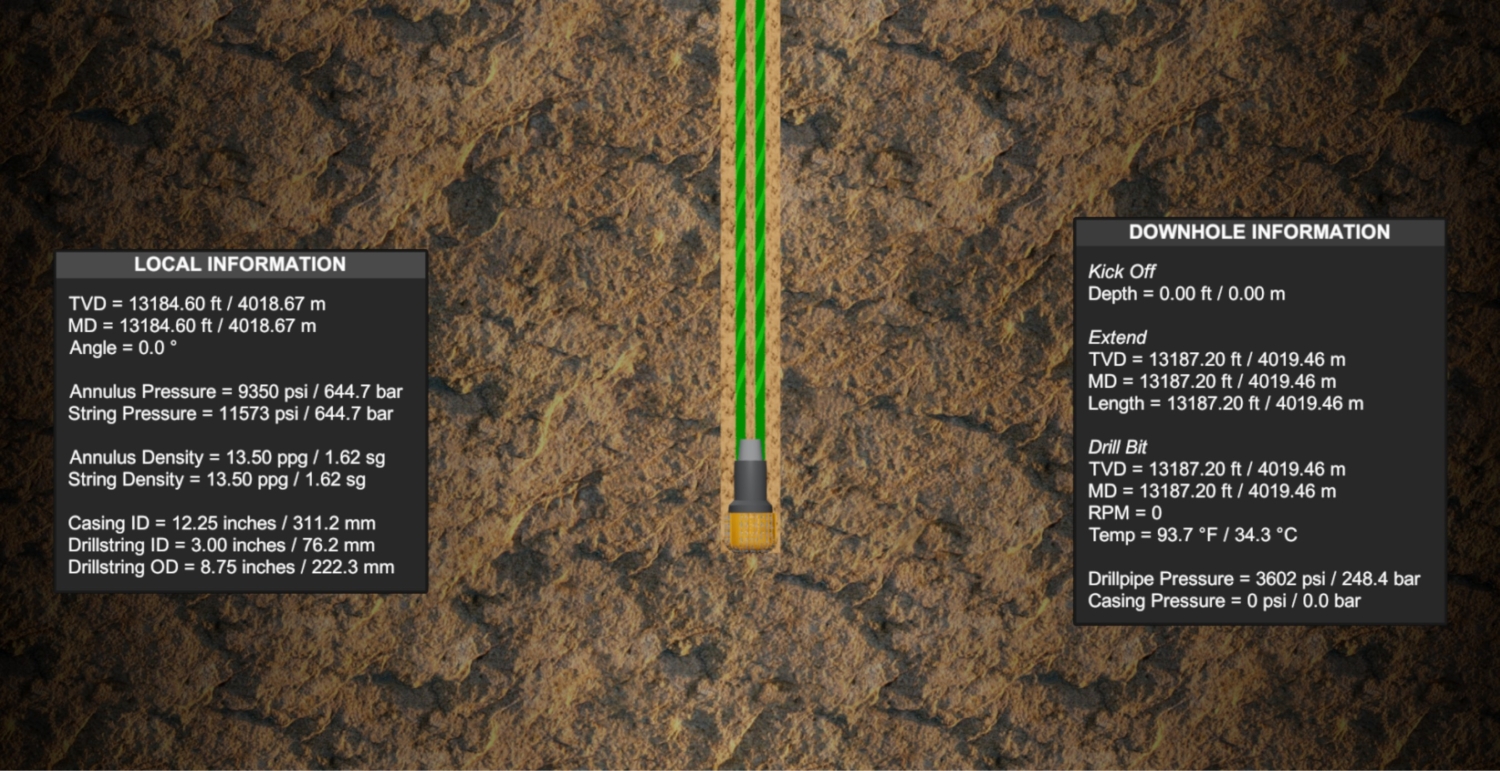

The accurate representation of a conventional rig floor and 3D graphics create a highly realistic and immersive simulation environment bringing the rig to the trainee.

Both simple and highly complex tasks for land and offshore operations can be recreated to verify skills and competency in real-world situations.