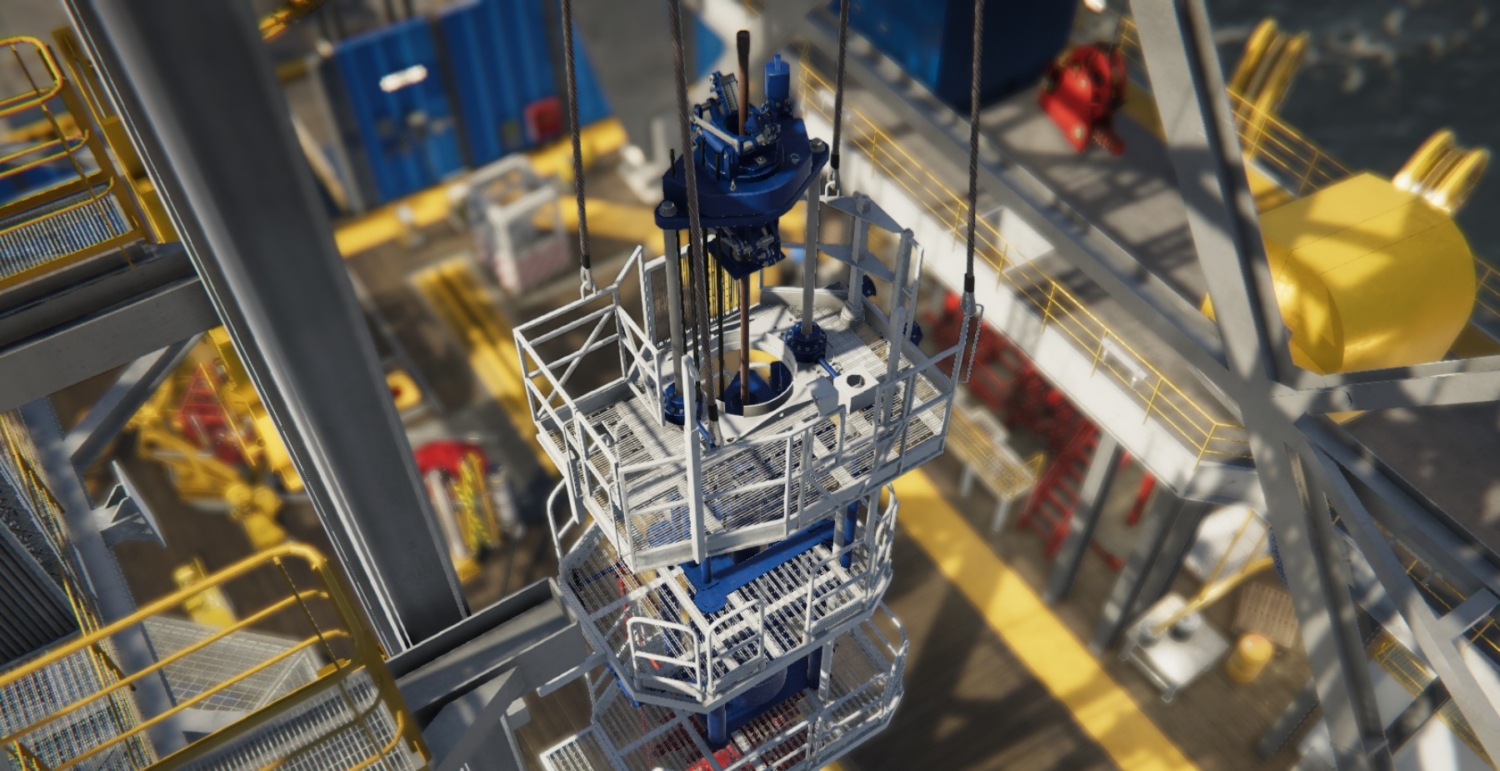

The simulator can be customised to emulate specific land rigs and equipment which enables operators to practice in their own real-life environment.

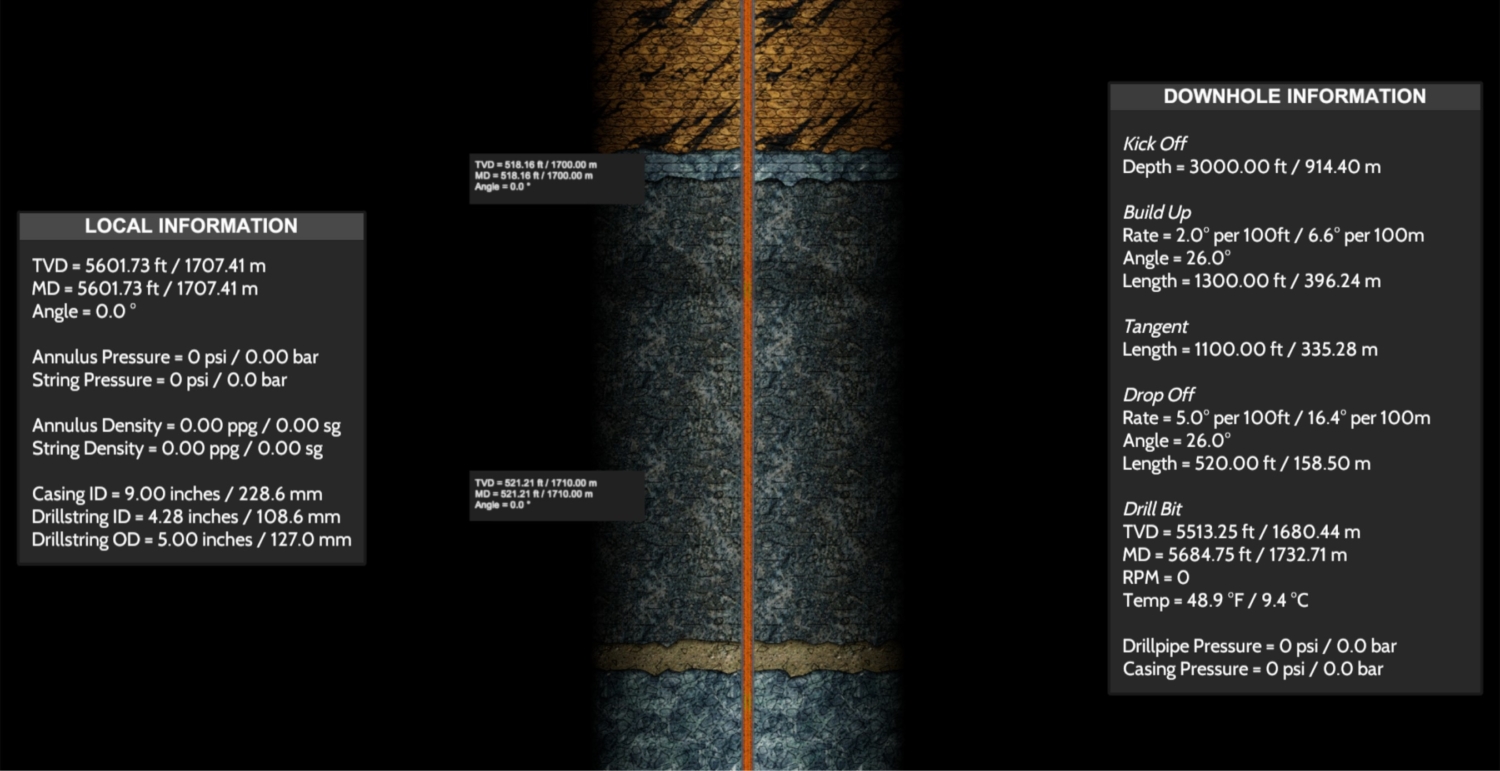

DrillSIM:600 combines 3D surface and downhole graphical views with realistic rig equipment sounds and functionalities for a truly immersive learning experience.